Ready to bond

Ready to bondA total of 5 hours working on the keel weights enabled me to cut 5 extra lead pieces, clean all the remaining bits with white spirit plus assemble and bond 20 of them. Bonding 20 pieces actually entails applying Evo-stik to 38 surfaces!

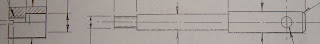

Retaining pin and nut (Not to scale)

Retaining pin and nut (Not to scale)Another 27 pieces have to be added, to complete the starboard weight, and possibly 4more pieces will be needed for the port weight. Another two sessions could see the weights bonded. I shall have to do a bit of shaping and filling to make them smooth. Then will come the tricky bit of drilling through them to accommodate the two transverse retaining pins. When the starboard weight is slotted onto the retaining pins, vertical locking pins can pass through holes drilled from the top of the starboard weight so that the locking pins can also pass through holes in the transverse pins.

Locking pin (Not to scale - the retaining pin is the larger of the two)

Locking pin (Not to scale - the retaining pin is the larger of the two)The reason for having two keel weights is for ease of transporting them from the car to the boat. The boat is laid on her port side so that the keel can be partially pushed into the keel box, then she can be supported by her keel so as to be ready for slotting the starboard weight onto the retaining pins. When that’s been done, locking pins are pushed home. When not in use the locking pins are retained in their holes by a thin flexible cord which is attached to the aft end of the weight. This cord sits in a fore and aft channel along the top of the weight.

Note

I am comforted by the fact that Ron Cannings has said he can make the stainless steel parts for ‘Sharpy’. He hopes to start on them in about three week’s time. His workshop is at Rice and Coles, Burnham-on-Crouch where ‘Ladybird’ is currently laid up.

No comments:

Post a Comment